APPLICATIONS The use of infra-red technology can be employed in a variety of applications across a wide range of different industries.

|

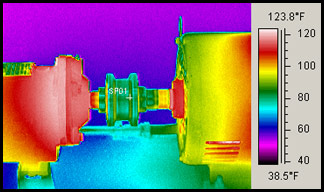

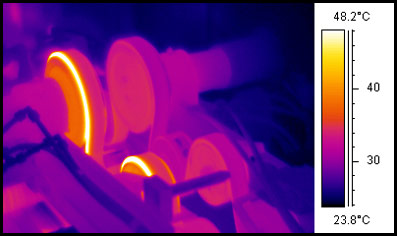

In all plants there are diverse collections of equipment that can be successfully inspected using infrared thermography. For most mechanical equipment the techniques used to inspect the equipment are straightforward, but specific knowledge and experience with some equipment is often required. You should know the basic operation and heat flow characteristics of the machinery, understand heat related failure mechanisms, have safety inspection procedures and observe the machinery during start-up and cool down as well as during normal operation. No one knows the equipment in a plant better than the plant personnel themselves do. It is very helpful to have past experience with the equipment and thermal images of the equipment during normal operations. Examples include: · Faulty bearings · Over or under greasing / maintenance · Misalignment · Component failure · Windings problems Mechanical Drive Inspections

ADDITIONAL INFORMATION:

|

![]()

INFRARED CERTIFIED

Level II Certified Thermographer

CEM® Certified Energy Manager

AHIT CERTIFIED

Master Building Inspector